Hot plate welding machine

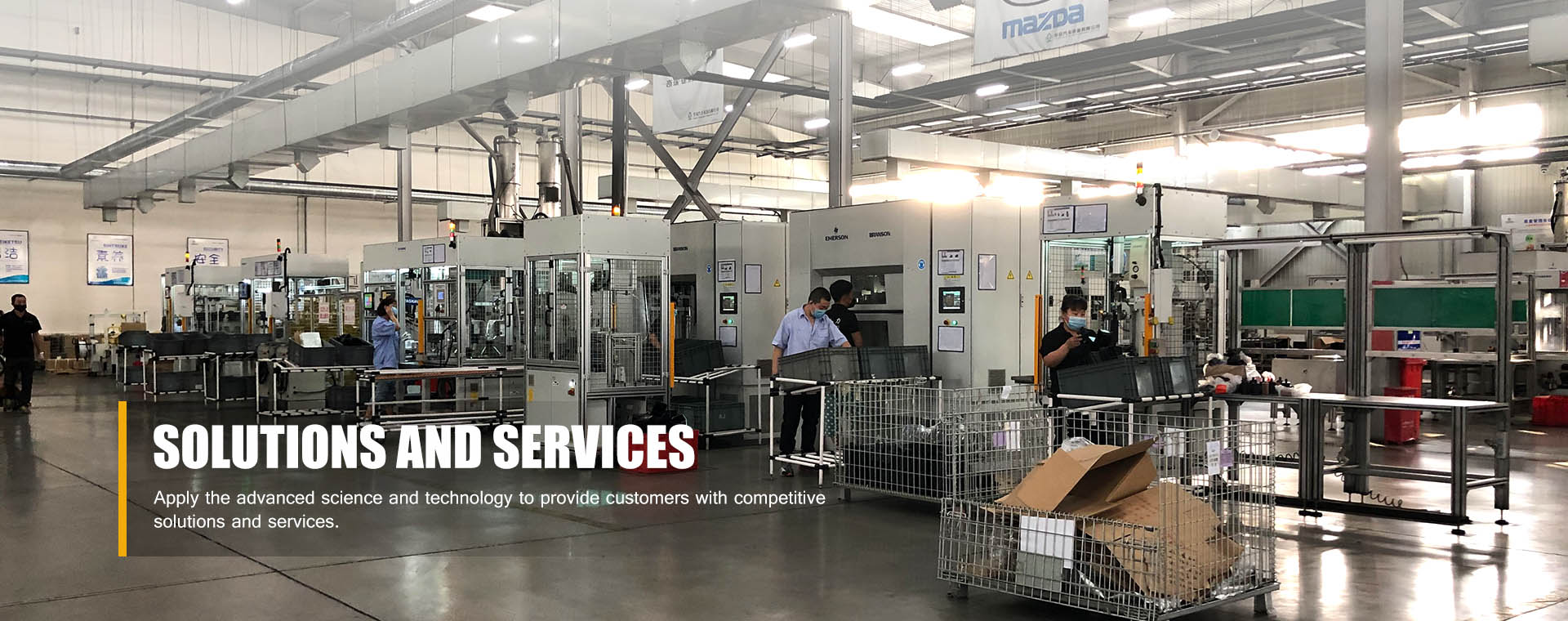

Hot plate welding technology is suited for large polyethylene, acrylic, polypropylene, or polyamide parts, in a wide range of applications. Hot plate welding machine for car canisters, air oil filters, oil mist separators, water tanks, car lights, air inlet pipes, glove boxes and other products. The action flow of the machine is controlled by PLC+HMI; the movement mode is servo and pneumatic.

Our hot plate welding equipment mainly includes:

● Horizontal servo hot plate welding machine, plastic welding equipment for welding of materials such as PE PMMA PP and PA

● Customizable infrared hot plate plastic welding machine suitable for PVC PS PP PE and other plastic materials

● Plastic products hot plate welding machine

It is equipped with more than ten types of sensors, such as maintenance door control sensor, operation port safety door control pressure sensor, various motion displacement sensors, welding pressure sensors, vacuum adsorption pressure sensors, clamping position sensors, power controllers, air supply pressure sensors, temperature sensors And welding parts position sensors are used to ensure stability and safety; the temperature control program independently developed by our company, combined with foreign advanced module hardware, can accurately control the temperature of different levels of hot molds on the man-machine interface, and accurately display the work of the heater Conditions, such as heater damage, temperature compensation, alarm of the upper and lower temperature limits, and the current status of the temperature in each area, are used for temperature control.